Driving the future: Polymer Injection Technology

Liberty OneSteel is shaking up the global construction industry and redefining steel as a green building material, all thanks to old car tyres.

Liberty OneSteel is reinventing the wheel with its world-first Polymer Injection Technology (PIT).

PIT prevents millions of old car tyres ending up in landfill while reducing the economic and environmental costs of steel manufacturing. Importantly, PIT doesn’t have any adverse effects on steel quality and it improves the environmental sustainability of the steelmaking process.

For builders, engineers and architects, this means they can take advantage of steel's strength and flexibility while boosting their environmental credentials. In fact, using PIT will earn one Green Star point if using reinforcing steel in buildings.

Savings of 15–35 per cent on total carbon injectant costs makes the technology attractive for fabricators, distributors and developers, who can expect improvements in yield and productivity, inject oxygen consumption, refractory and electrode consumption and injection system wear.

How it works

PIT was developed in collaboration with the University of New South Wales (UNSW) as part of Liberty OneSteel's commitment to innovation and thought leadership.

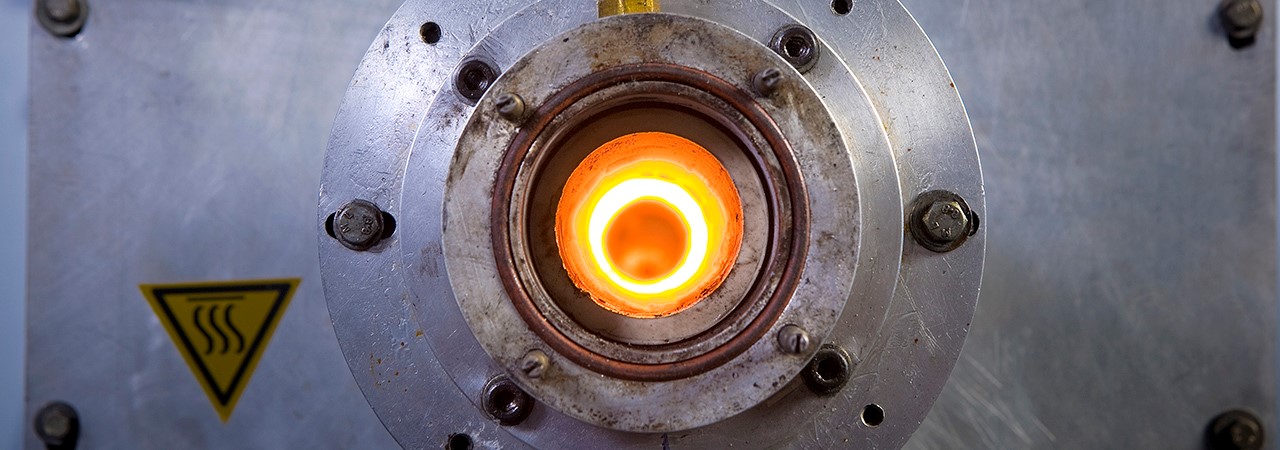

It uses recycled polymers (particularly old car tyres and high-density polyethylene plastic) as alternate carbon injectants to produce the foaming slag required for the electric arc furnace (EAF) steelmaking process.

Conventionally, non-renewable coke or anthracite is used to produce the slag that acts as a blanket over the molten steel during the steelmaking process. This practice has faced criticism for its energy consumption, but PIT boosts the volume and foaming properties of the slag, which improves electrical energy efficiency by 3 per cent – a figure not to be sneezed at considering electricity costs can represent more than 20 per cent of the per-tonne cost of steel.

PIT has been shown to perform better than metallurgical coke alone in EAF and can reduce the total amount of inject carbon required per heat by 10–20 per cent, while decreasing heat loss through the slag and sidewalls.

Ultimately, the technology delivers cost savings through reduced energy consumption, cheaper injectables and lower greenhouse gas emissions.

Global uptake

With global steel production at 1.4 billion tonnes in 2016 – a quarter of that manufactured in electric arc furnaces – PIT is playing a significant role in greening the industry.

Steelmakers across Europe and Asia have licensed PIT. But OneSteel is not resting on its laurels, instead driving innovation through ongoing work with UNSW to identify and develop processes for improving conventional steelmaking practices using recycled polymers.

The bottom line

Liberty OneSteel’s Polymer Injection Technology makes steel a more affordable and environmentally friendly building material. It not only diverts millions of tyres from landfill, but promises to slash greenhouse gas emissions at the world's 300 EAF steelmaking plants, which account for 25 per cent of crude-steel output globally.

So be an industry leader, not a tyre kicker, and get the jump on your competitors with PIT today.

For further details on Liberty OneSteel’s Polymer Injection Technology contact:

Catherine Skidmore

OneSteel Raw Materials and By-products Superintendent

e: steelmakingsolutions@onesteel.com

t: +61 (02) 9675 9959

Download the Polymer Injection Technology flyer.

Read more about Polymer Injection Technology in a recent article on the development of the technology.